Plastic is better known for its pollution figures than for its positive aspects. Of the great variety of plastics that we know today, their beginnings and the discovery of these compounds arose to solve human needs

“Ours will be remembered as the age of polymers,” said Nobel laureate Paul Jhon Flory, who also added: “The future belongs to technopolymers and special polymers that will be produced in perhaps slightly reduced quantities but which will be essential to the progress of humanity.”

Paul John Flory

The expansion of industrialisation in the 19th century required new materials, which, thanks to their transformation, allowed the manufacture of multiple articles. It generated a period of evolution that dubbed the Contemporary Age as the Plasticocene. The need for manufacturers to replace materials derived from nature, such as ivory and cochineal shellac (Kerria lacca), allowed chemists to research new compounds and create the first plastics:

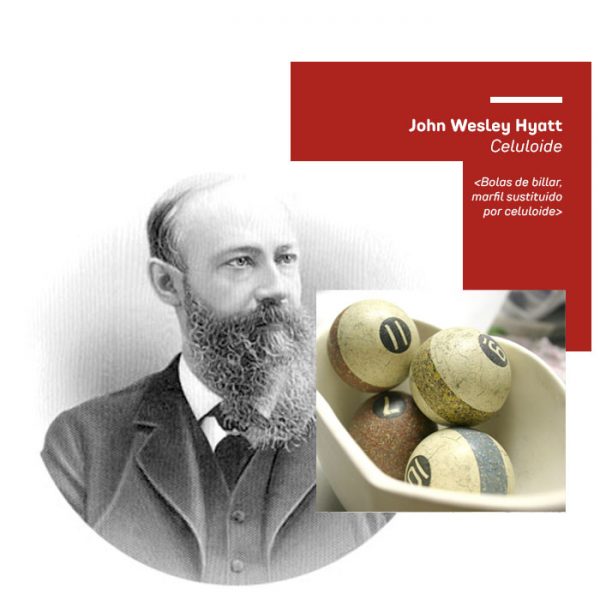

- 1865, John Wesley Hyatt chemically modified cellulose: celluloid, used to make billiard balls, to replace ivory. This happened when American manufacturers offered a reward of $10,000 to anyone who could replace the scarce and expensive ivory used to make billiard balls.

- 1897, Adolph Spiteler discovered, by mixing sour milk with formaldehyde, a protein plastic they called Galalite. The aim was to make a white board for writing, and by mixing these components, they visualised a material that was hard but easy to mould. They used it for buttons, combs, stationery…. They called it artificial ivory.

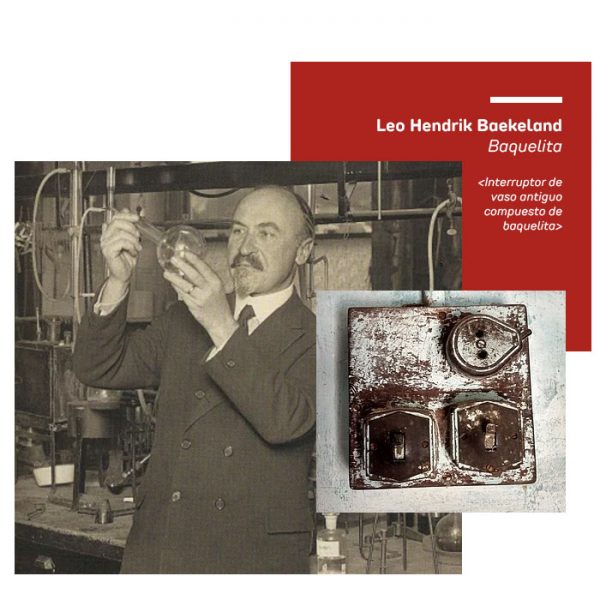

- 1907, Leo Hendrik Baekeland applied for a patent for a new compound, called Bakelite, to replace the cochineal shellac (a small red insect that lives in Southeast Asia). It was used in the insulation of electrical wires and 78 rpm gramophone records. Unsurprisingly, such a limited source of cochineal lacquer, so necessary for such applications, required a more accessible substitute. Later, several chemists realised that mixing different organic substances (phenol and formaldehyde) produced a hard material that ruined the laboratory vessels. They decided to study this new material and see what applications it could be used for.

- 1912, Fritz Klatte after generating a chemical reaction (acetylene with hydrochloric acid) produced vinyl chloride (PVC) without knowing it, but he did not see useful qualities so he abandoned the tests, leaving a patent that expired over the years. Fritz, like other chemists, began his research on the initiative of German businessmen, who thought they would make money by lighting homes with acetylene gas lamps. When new and efficient electric generators came on the market, they lowered the price of electric lighting and the result was deplorable. With all the acetylene unusable, these chemists began to look for possible actions with it. 1926, Waldo Semon independently discovered PVC, but he was able to take advantage of it because he saw its waterproof potential. Working for B.F. Goodrich, he realised that he could make a shower curtain out of this material. That is how he and his bosses patented it.

The etymological root of the word PLASTIC derives from the Greek word plástikós (meaning, mouldable), referring to the ease with which it can be moulded by applying heat, and thus be given the desired shape to construct almost any imagined element.

Transformation processes have evolved over the years, using increasingly skilled technology.

These materials developed as society prospered and needs increased. Industry was working with materials that came from nature and their destruction was advancing, which is when plastic became the ecological alternative.

Today, plastic is still an environmentally friendly alternative for many applications, as its characteristics (lightness, strength and recyclability) allow it to be so.